Is arc welding stronger than MIG

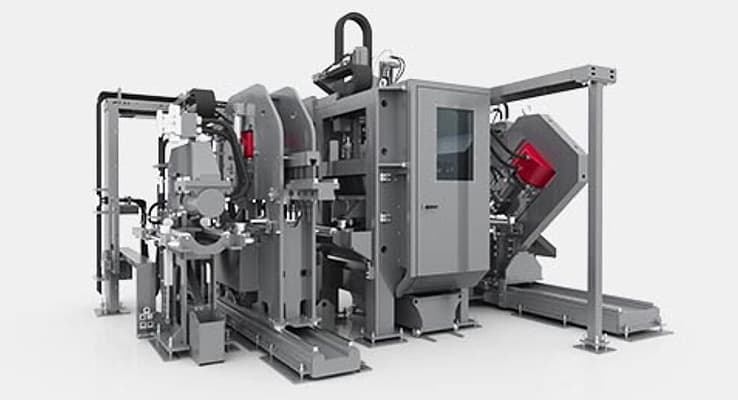

Clamps are released, and web is transmitted to the tacking device. Welding equipment is composed of a welding head and flux hopper, travel carriage with controls, and a 1,000 Amp electrical power source. Full-color projection systems with lasers can project all necessary information to enable operators to precisely tack-weld connections either on the beam of other connections.